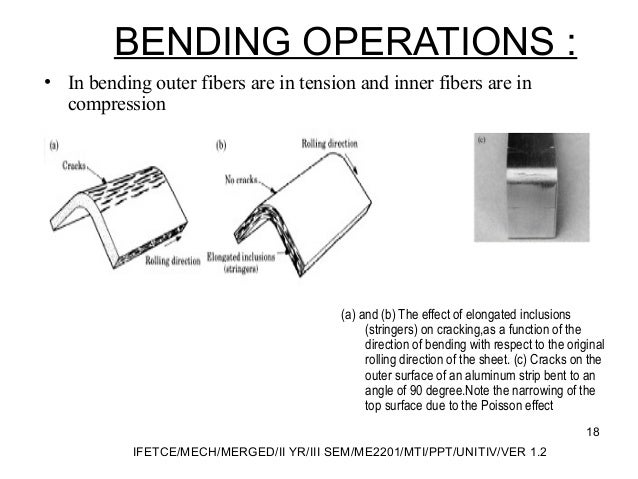

Also know that for the best results and fewer cracks on the outside of the bend the bend line should go across or diagonal to the material grain when and where possible.

Bending aluminum sheet grain.

In other words if you re bending 1 8 sheet use a tool with a 1 8 radius to form the inside of the bend.

Pieces 22 long by 1 75 wide by 0 63 thick.

Bending with the grain gives a different result than bending against it.

Bend angles also can be less consistent.

The grain direction is established during the metal rolling process.

Inside bend radius 0 19.

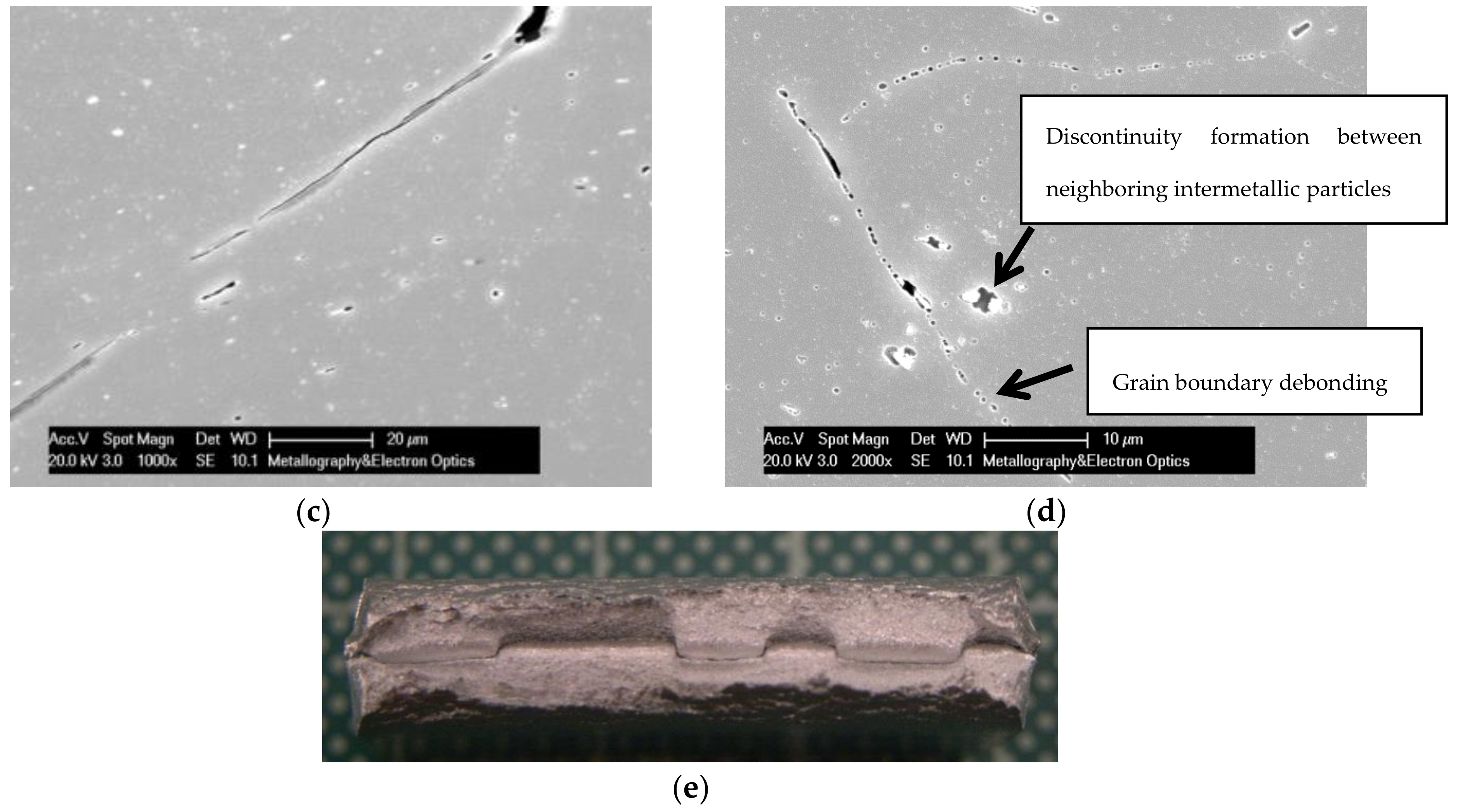

When bending aluminum know that the smaller your inside bend radius the larger the chance that cracking will occur in the part.

That said forming with the grain takes less pressure to make a bend.

For 0 5 in thick 7050 aluminum the minimum bend radius may be specified as much as 9 5 times material thickness.

The harder and thicker the plate is the greater the minimum bend radius.

If you re bending 0 020 thick material use a 0 020 radius.

General advice on aluminum.

The trend is obvious.

When bending high strength materials such as spring or high carbon steel you should orient the part so that it can be bent against the grain.

Bending the sheet metal longitudinally with the grain allows those grains to separate at the grain boundaries.

For most applications with stainless steel or aluminum you can get away with a zero radius bend on anything under 0 050 thick.

This is important to note especially with aerospace and aviation applications since bending with the grain or parallel to the grain direction can result in material failure.

Bending with the grain may result in cracking or.

This could be either problematic or catastrophic depending on the application of the end product.

Again the minimum inside bend radius is even larger when bending with the grain.

Bending 2024 t3 grain direction considered.

The bend is along the long dimension.