Laminated bus bar is an engineered current carrying component consisting of layers of fabricated copper separated by thin dielectric materials laminated into a unified structure.

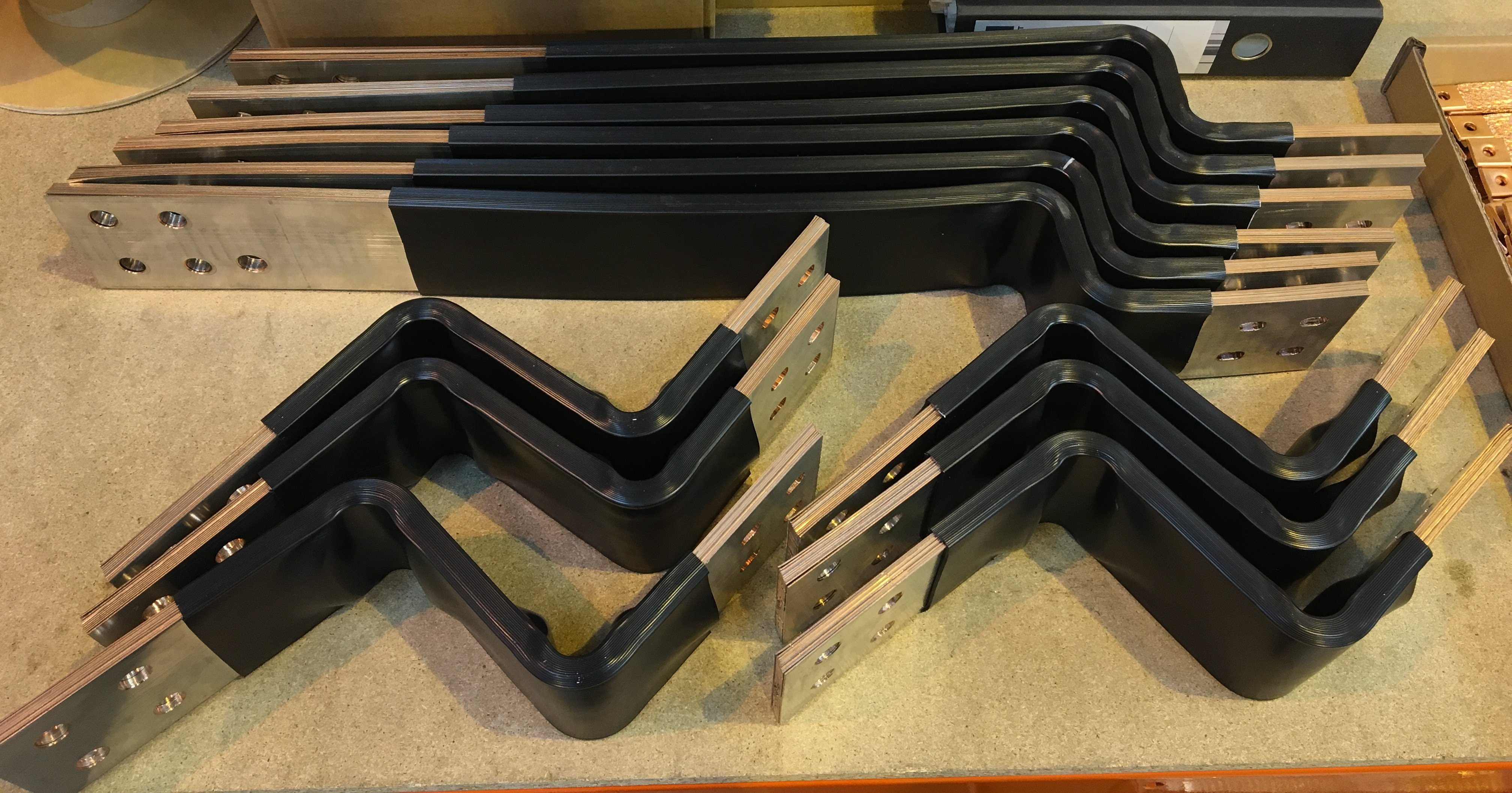

Bending laminated bus bar.

A laminated bus bar is an engineered component consisting of layers of fabricated copper separated by thin dielectric materials laminated into a unified structure.

All types of lug configurations are possible with less restriction to tolerances making this remarkable bus a cost saving alternative to electrical cable with pre set lugs.

The stampings are stacked on a fixture in alternating relation with similarly shaped layers of insulation which have marginal edges that overlap around the edges of the.

Pa12 insulation does not allow moisture contaminants to wick under insulation like traditional round cable and laminated bus bar constructions.

3d bending technology requires no tooling for forming your required design.

Dielectric rigidity of 20 kv mm.

These bus bars are made from thin copper plate stampings having flat transverse conductor strips connected at their ends to integral longitudinally extending looms or webs which hold the strips in spaced relation.

Because of it s feature of good conductivity flexible easy to install and space saving flexible busbars are.

They are produced by process of welding stamping plating forming insulation and so on.

We have copper bus bar flexible busbar braided copper st.

Unlike bent solid bus bar flexible insulated bus bar can be punched or drilled after bending.

They are available in various sizes and shapes some as big as a.

Laminated bus bars are used to conduct current in power.

The plating can be tin and nickel.

The insulation can be pvc dipping and pe heat shrink tubing.

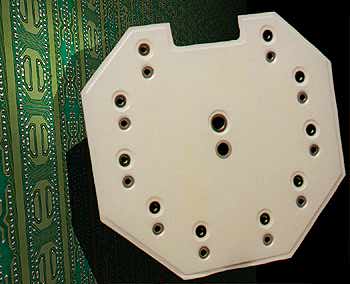

A laminated bus bar assembly consisting of three power layers and one signal layer with a total of 59 conductors providing a very low inductance power path and complete gate drive circuitry all designed for a wave solder assembly process.

Sizes and applications range from surface mounted bus bars the size of a fingertip to multilayer bus bars that exceed 20 feet in length.

Rhi electric co ltd is specialized in design development and production of new energy products.

Laminated bus bars offer several advantages improved reliability and reduced system costs.

This bus bar is used in a system powered by 24 mosfets.

Tin plated copper foil laminated bus bars are made of copper foil thickness from 0 1 to 1mm.

Triton manufacturing laminated bus bars provide superior electrical and mechanical performance requiring less space with improved quality and reliability.