Now slip the aluminium sheet between the two angle s and roll the bender forwards while exerting downward body weight pressure until the fold is 90 degrees.

Bending light weight aluminum sheets.

Thinner aluminium bends easier just like steel but you also want structure so it holds its shape.

Simply multiply the appropriate alloy density see chart below by the length width and thickness of the required part see worked example below and note that we have used the density of alloy 2014 as the basis for our calculations.

Free delivery with 45 order.

Aluminum union jack mill sheet model 57573 7 68 7 68.

Go slowly sheet aluminum is very soft so you won t need to use much force at all.

The spacing between the two nuts and bolts determines the maximum width sheet that can be bent.

So your best bet is to buy something like 0 5 mm and 1 mm and give it a go going thicker if you need it to hold shape better and thinner if it isn t bending to shape very well.

M d building products 1 ft.

The weight of sheet is easily calculated.

Mark where you want your bends.

Diamond tread light weight aluminum sheet model 57574 8 99 8 99.

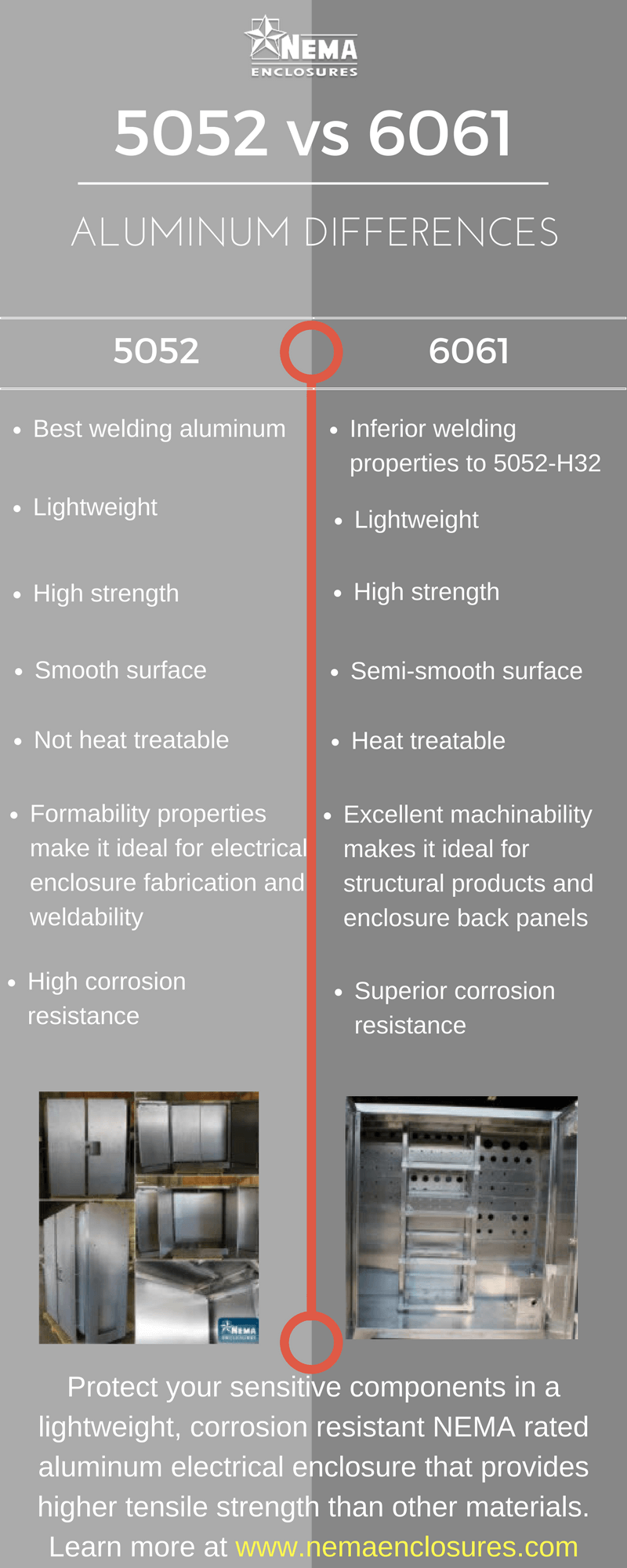

Ideally part designers should know that when it comes to aluminum grades 3003 and 5052 will bend 6061 will not.

M d building products 1 ft.

Lift the handles of the apron to bend your sheet to the desired angle.

How to calculate the weight.

Remove any unwanted corners.

Free delivery with 45 order.

As the apron comes up it will gently fold the sheet around the edge of the clamp bar at your chosen bend point.

.JPG)